Excel Polymer Limited

We, Exel Polymer Ltd., are proud to be one of Bangladesh’s leading manufacturers of premium expanded Polyethylene (EPE) foam and insulation solutions. Specializing in innovative, eco-friendly, and durable foam products, we cater to a wide range of industries, including packaging, construction, automotive, mattresses and more. Our products are designed to offer superior insulation, cushioning, and shock absorption, ensuring the best protection for your goods and materials and from temperature.

With a commitment to quality and sustainability, we leverage advanced technology and stringent quality control to deliver reliable and customizable solutions that meet your unique needs. Whether you require standard foam products or bespoke designs, our expert team is dedicated to providing tailored solutions that help you achieve your goals.

At Exel Polymer Ltd., customer satisfaction is at the heart of everything we do. We continuously innovate to enhance our product offerings, ensuring that our clients always receive the best in performance, reliability, and value. Explore our diverse product range and discover how we can help your business grow with efficient, high-performance foam materials. Your success is our commitment!

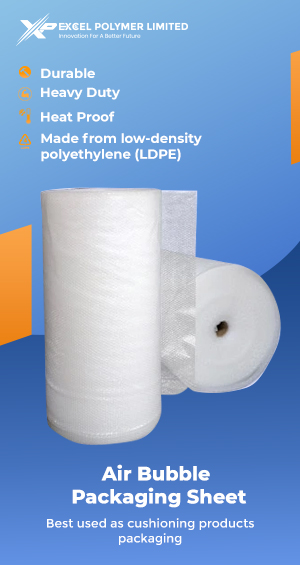

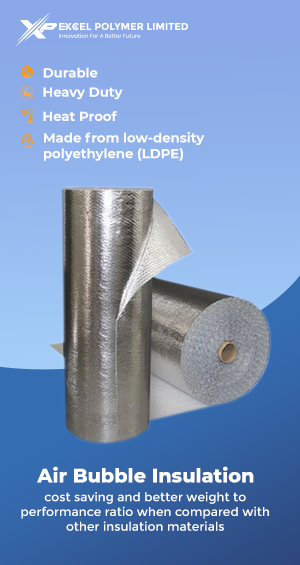

PRODUCTS

Sectors Where We serve

Expanded Polyethylene (EPE) foam is widely used across various industries due to its lightweight, flexible, durable, and shock-absorbing properties. Here are some key industries that rely on EPE foam:

Objective

The objective of a Exel Polymer Ltd. in Bangladesh would typically focus on several key areas, including:

Objective

Mission

Mission of Exel Polymer Ltd.: “To provide innovative, high-quality, and sustainable Polyethylene (PE) foam solutions that meet the evolving needs of our customers across diverse industries, while maintaining a commitment to operational excellence, environmental responsibility, and contributing to the economic growth of Bangladesh.”

Vission

To be the leading innovator in sustainable PE foam solutions in Bangladesh, driving excellence in quality, customer satisfaction, and environmental stewardship.

Objective

Services

The services offered by Exel Polymer Ltd. in Bangladesh would likely encompass a range of solutions related to the production and supply of polyethylene foam. Here’s a breakdown of potential services:

Specialty

The specialty of a PE Foam factory like Exel Polymer Ltd. in Bangladesh would likely revolve around its unique strengths, industry focus, and the quality of its offerings. Here are some possible specialties that could distinguish Exel Polymer Ltd.

Welcome to Excel Polymer Ltd, a trusted name in the manufacturing of high-quality PE foam and insulation solutions. As the Managing Director, it is my pleasure to introduce you to our company, where innovation, precision, and customer satisfaction are at the heart of everything we do.

At Excel Polymer Ltd, we are committed to delivering versatile and sustainable PE foam and insulation products that meet the diverse needs of industries worldwide. Our state-of-the-art facilities and experienced team enable us to provide custom solutions that exceed expectations in terms of performance, durability, and cost-efficiency.

Thank you for choosing Excel Polymer Ltd as your partner in excellence. We look forward to supporting your business with cutting-edge solutions and exceptional service.As a corporate entity, we believe in only one motto i.e., to provide best services and create value for our clients.

Warm regards,

Md. Tazbir Haque

Managing Director

Excel Polymer Ltd.

VALUED CLIENTS

- Construction Industry:

– Steel structure building components, laminated insulation, and duct insulation for commercial and industrial buildings.

- Manufacturing and Industrial:

– Steel structure building components for industrial facilities and insulation materials for manufacturing plants. - Textile and RMG (Ready-Made Garments):

– Packaging materials, floor mats, and exercise mats for textile manufacturing and garment packaging.

- Transportation Infrastructure:

– Steel components for bridges and overpasses, insulation materials for related applications.

- Energy and Power Plants:

– Insulation materials for energy efficiency in power plants, steel components for construction.

- Food Processing Industry:

– Insulation materials for temperature control in food processing, steel structures for processing plants.

- Pharmaceutical Industry:

– Insulation for temperature-sensitive processes, steel structures for pharmaceutical facilities.

- Footwear Industry:

-Packaging materials, floor mats, and potentially PE foam for shoe manufacturing and packaging.

Sectors Where We serve

Expanded Polyethylene (EPE) foam is widely used across various industries due to its lightweight, flexible, durable, and shock-absorbing properties. Here are some key industries that rely on EPE foam: